M-BRACE Mount LRF Bridge

Not compatible with M-Brace two-piece rings.

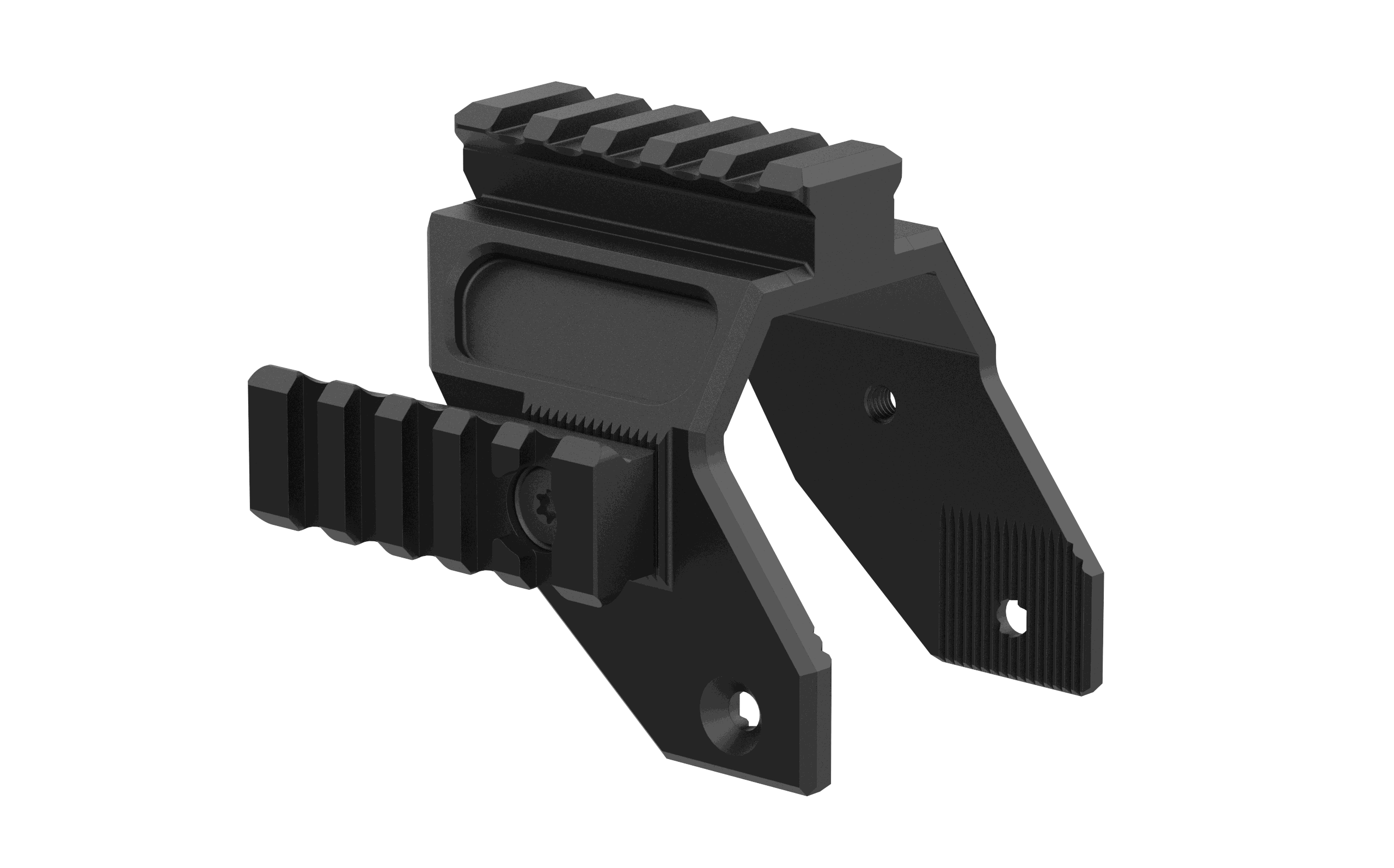

M-Brace Laser Range Finder Bridge

Securely attaches to the M-Brace Scope mount to support your laser range finder.

Mounting Points

Accessory Pic Rail or Bubble Level can be mounted to LRF mount or directly to M-Brace Mount

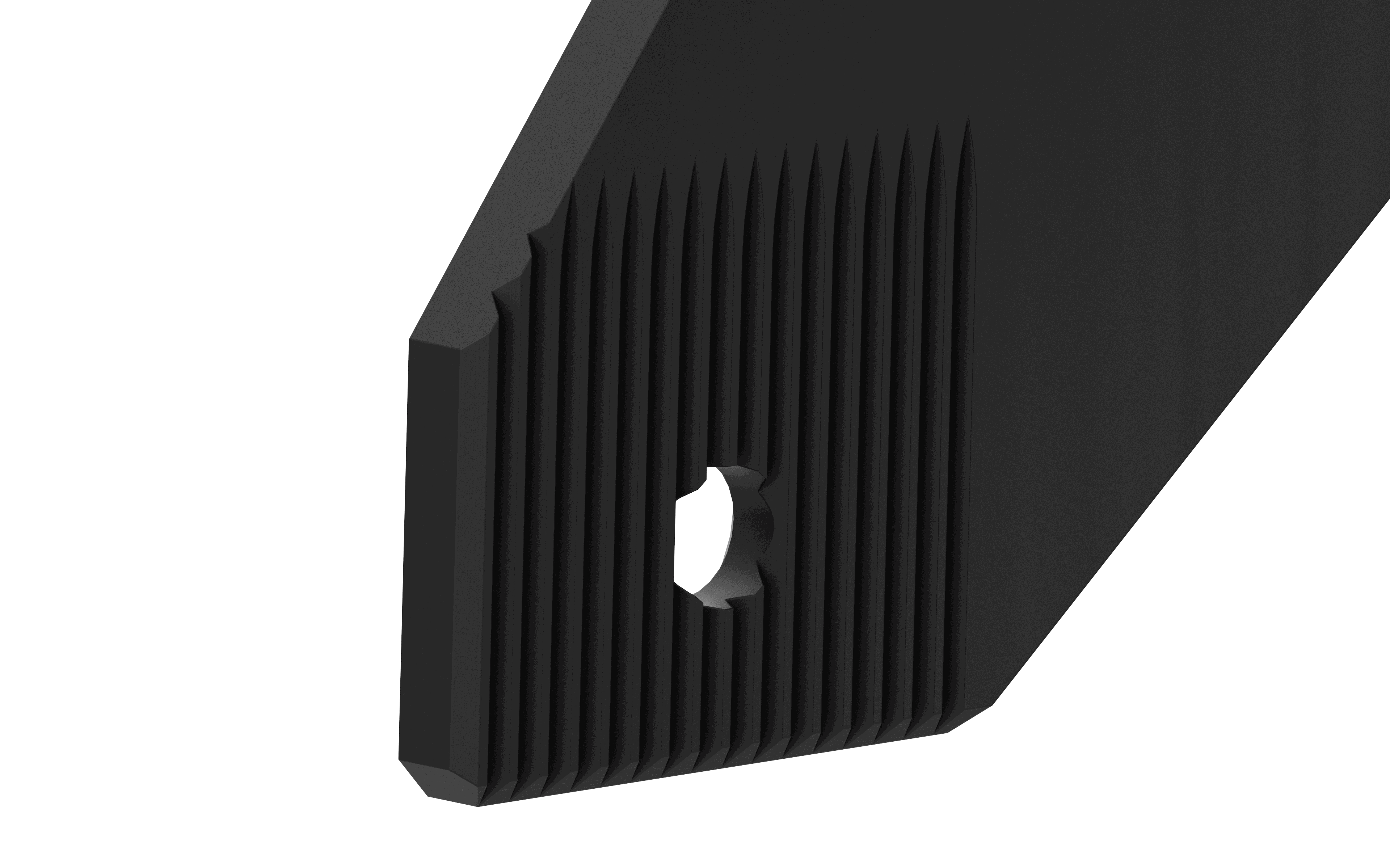

Locking Interface

Serrations positively locate the rail and withstand recoil forces without moving or slipping.

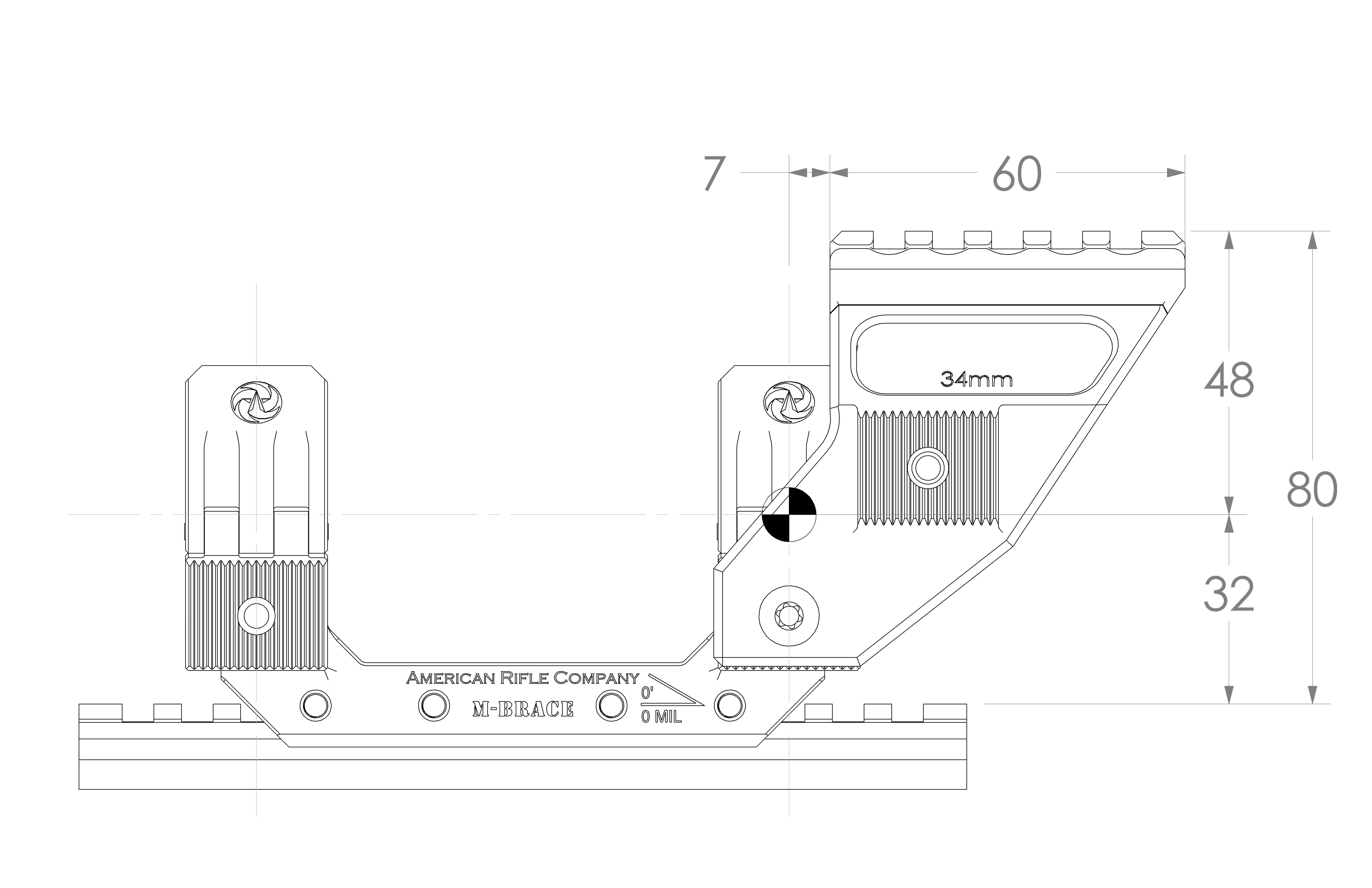

Mount Angle

The attachment points on the mount include the angle of inclination. If the scope is at 20 MOA, the LRF Mount pic rail is at 20 MOA.

What’s in the Box

LRF Mount

Mounting Screws, two M5 x 16mm T25 Torx. Uses the same T25 tool as the M-Brace.

Overview

7075 Aluminum

Picatinny (MIL-STD-1913) rail

Compatible with American Rifle Company M-Brace Mount

Weight with mounting hardware for 34mm width 4.5 oz (127 grams)

Proudly engineered and manufactured in the USA

M-BRACE Mount > M-BRACE Mount & Accessories >

Details

M-BRACE is The Ultimate Scope Mounting System.

M-BRACE is derived from a first principle approach to defining and solving the problem of securely attaching high-precision optical devices to a high-precision rifle.

The M-BRACE Scope Mount boasts a serrated interface to which the M-BRACE LRF (Laser Range Finder) Mount can be securely attached.

Even under heavy recoil, the serrations immobilize the connection between the scope mount and the LRF mount so you can be sure that alignment between your scope and ranging or targeting device remains uncompromised.

Inspired by Hirth couplings used for high power transmission in gas turbines and for high precision assembly in machine tools, the serrations are machined into both sides of the strongest portion of the M-BRACE Scope Mount. In fact, the placement of the serrations takes full advantage of the structural system resulting from cooperation among the mount, receiver, and scope. Thus, recoil forces are symmetrically and efficiently transferred through this structural system and distributed into the rifle receiver.

The distribution of recoil forces is important because they can be quite high and significantly stress the scope mounting system. Consider the Wilcox Raptor weighing almost 500 grams (1.1 pounds). The preferred mounting location of this device is above the forward end of the scope. Due to inertia and recoil, forces can easily exceed 900 N (200 lbs). If these forces are to be transferred through the scope mount and into to the rifle, well-designed connections and symmetry should be used to distribute and to minimize the resulting stress within the mount and within the scope.

The recoil forces are not concentrated in any one portion of the M-BRACE Scope Mount, or even worse, into a single scope ring cap, as is the case with competing products. Nor are they applied asymmetrically into the mount as is the case with another competitor.

No other system currently available provides for a connection between a scope mount and an LRF mount as securely and effectively as does the M-BRACE. Nothing is even close.

Extremely strong and light-weight, CNC machined from 7075 aluminum alloy and anodized for excellent corrosion resistance and a matte-black finish.

Torque spec: 6.2 Nm (55 in-lbs).

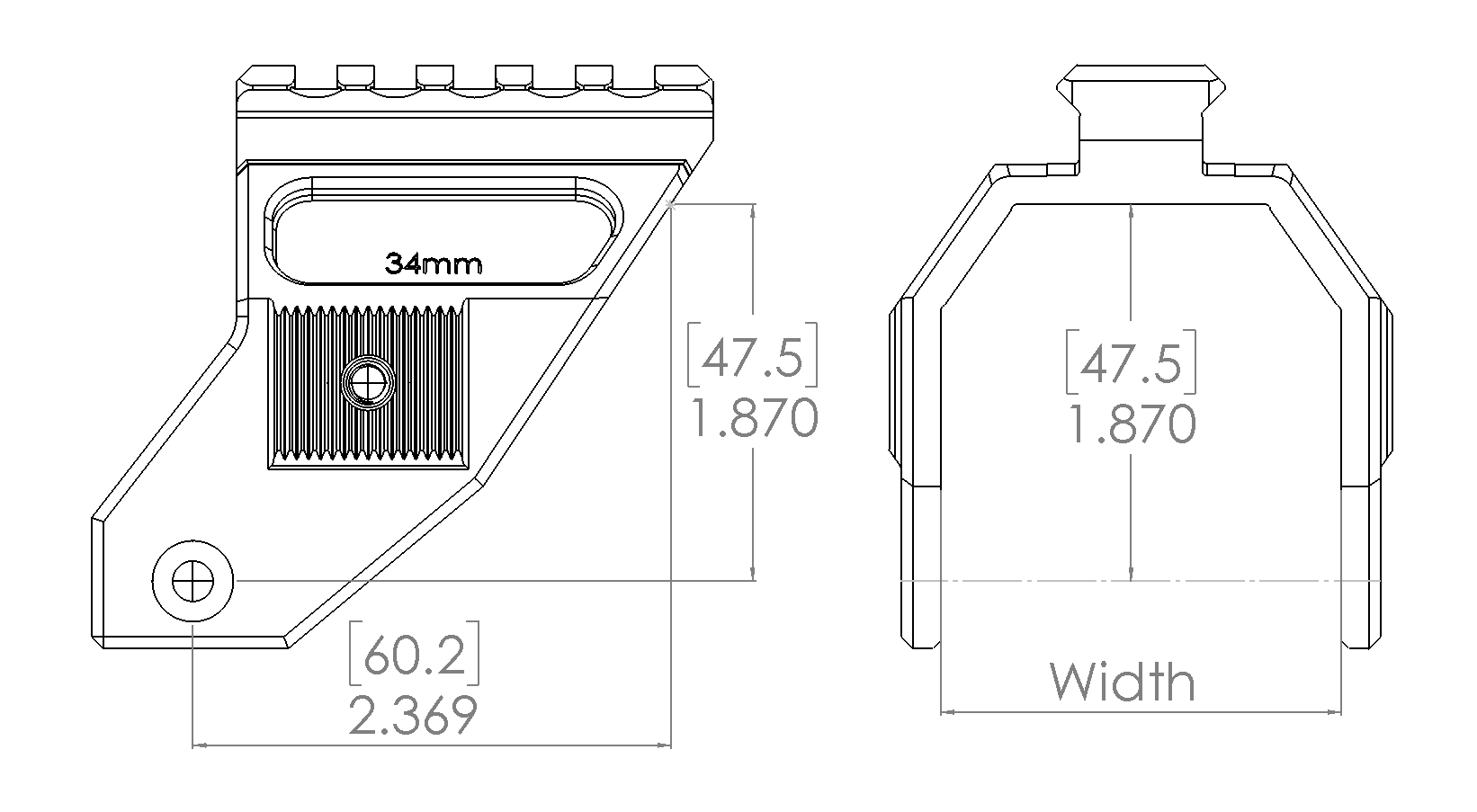

Dimensions and Weight

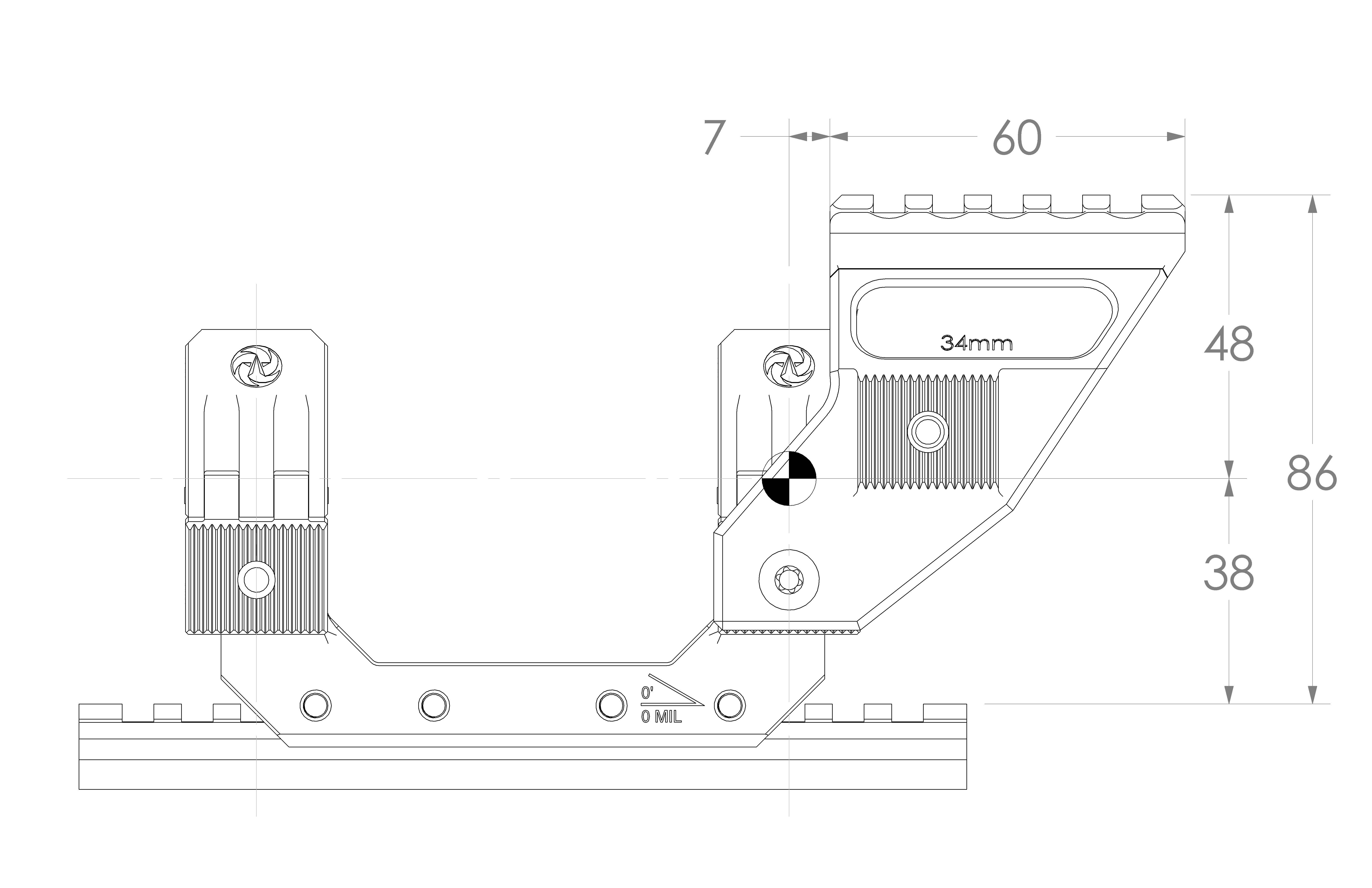

LRF Mount on 32mm Height M-BRACE

LRF Mount on 38mm Height M-BRACE

LRF Mount Internal Dimensions

*width varies by scope tube diameter

Weight (ounces) and mass (grams) for each available size includes two mounting screws. Weighed on a scale with 0.1 oz resolution.

| Fits 1" & 30mm Dia. Mount | Fits 34mm Dia. Mount | Fits 35 & 36mm Dia. Mount | Fits 40mm Dia. Mount | |

| LRF Mount & 2 screws | 4.3 oz 122 g | 4.5 oz 127 g | 4.5 oz 127 g | 4.6 oz 130 g |

| Width | 1.827" 46.4mm | 1.984" 50.4mm | 2.063" 52.4mm | 2.220" 56.4mm |

Notes

- The EOTECH Vudu 5-25x50 is not compatible with our LRF mounts.